Key Takeaways

- Winter amplifies all utility strike costs by 30-50% due to frozen ground, limited daylight, and year-end deadline pressures

- ROI ranges from 273% to 2,221% across multiple independent studies, requiring only 1-2% of the project budget

- A combined technology approach is essential; no single method detects all utility types or overcomes winter challenges

- Projects ≥$3 million in urban areas show the highest returns, particularly deep excavation work (bridges, widening, new construction)

- Early season scheduling (November/early December) is critical for completing work before severe weather destroys markings

Every winter, construction projects across the country face a silent threat that transforms routine excavation into financial catastrophe. Frozen ground, obscured markers, and compressed year-end schedules create the perfect conditions for utility strikes, accidents that occur once every six minutes nationally and cost an average of $5,717 per incident before accounting for delays, redesigns, and regulatory penalties.

Winter magnifies these costs by 30-50% while simultaneously making emergency response slower and repairs more difficult. Yet despite these elevated risks, proven technology exists that delivers returns exceeding 2,000% on investment.

This article examines how professional utility locating protects both budgets and schedules during winter construction, backed by data from Louisiana DOTD, FHWA, and multiple university studies analyzing hundreds of projects.

Why Winter Construction Projects Need Professional Utility Locating

Winter construction amplifies every risk associated with underground utilities. When frozen ground meets compressed schedules and obscured markers, the probability and cost of utility strikes increase dramatically.

What is utility locating:

Subsurface Utility Engineering (SUE) uses technology to accurately locate underground utilities before construction begins. The process operates across four quality levels, D through A, with Level A providing precise three-dimensional mapping through vacuum excavation or “potholing.” This precision matters: over 20 million miles of underground utilities crisscross the United States, and nationally, a utility line is damaged approximately once every six minutes.

Winter’s unique challenges:

Frozen ground becomes as hard as concrete, preventing standard equipment operation and ground rod insertion. Snow buries markers and destroys paint marks through wind or plowing. Equipment batteries drain rapidly in cold temperatures. Limited December daylight compresses available work hours while year-end deadlines create intense schedule pressure.

Michael Jensen, a locating expert with over a decade of field experience, confirms: “You’re at a lot higher risk for damages during the winter.” These conditions amplify all utility strike costs by 30-50% compared to temperate months, making professional winter construction utility locating essential for project success.

The True Costs Of Utility Strikes In Winter Construction

A single utility strike cascades into multiple cost categories, each magnified by winter conditions. What appears as a simple excavation error rapidly escalates into a project-threatening financial event.

Industry-wide impact:

Utility strikes cause $1.7 billion in annual property damage across the United States. When accounting for all construction errors, including utility conflicts, the total reaches $177.5 billion annually. The average individual strike costs $5,717, and that figure excludes project delays and redesign expenses. Human costs prove even steeper: 1,906 injuries and 421 deaths occur annually from utility strikes.

Major Cost Categories of Winter Utility Strikes

| Cost Category | Winter Impact | Estimated Range |

| Emergency Repairs | Frozen ground requires specialized equipment; 30-50% cost increase | $10,000 – $100,000+ |

| Project Delays | Limited daylight and year-end deadlines amplify impact | $85,000 – $500,000+ |

| Cleanup & Remediation | Spills are harder to contain in frozen soil | $35,000 – $250,000+ |

| Penalties & Fines | Year-end deadline violations; regulatory penalties | $25,000 – $150,000 |

| Equipment Damage | Strikes + extreme cold operation costs | $18,000 – $75,000 |

How strikes cause change orders, rework, and downtime:

Mid-project utility conflicts force expensive redesigns under deadline pressure. Construction crews and equipment sit idle until repairs are complete, extending labor and rental costs daily. Compressed winter schedules mean delays carry amplified financial consequences, potentially affecting annual budgets and year-end financial obligations.

The Proven ROI: How Utility Locating Saves Money In Winter

Multiple independent studies demonstrate exceptional returns from investing in professional utility locating. The financial case becomes even stronger during the winter months when strike costs escalate.

Return on investment data:

Louisiana DOTD research found $2.73 saved for every dollar spent on SUE services. The landmark Purdue/FHWA study analyzing 71 projects revealed $4.62 saved per dollar, with 96% of projects showing positive returns. North Carolina data proved even stronger at $6.63 saved per dollar. Penn State’s analysis reached $22.21 saved for every dollar invested. These returns require only 1-2% of the total project budget for utility locating services.

Project delivery improvements:

FHWA studies document 12-15% reductions in project delivery time from systematic utility risk management. GP-Radar analysis shows a 40.33% reduction in relocation and change order costs when utilizing SUE standards A or B. On a typical $1 million winter project, these improvements translate to over $360,000 in potential savings, demonstrating clear ways to save money on excavation through proactive planning.

Key Ways Utility Locating Prevents Costly Delays:

- Eliminates excavation errors requiring rework in frozen ground

- Prevents safety shutdowns following utility strikes

- Avoids redesign delays when conflicts are discovered mid-project

- Stops equipment damage requiring rental or repair time

- Prevents weather-related re-marking by completing work early in the season

- Enables accurate contractor bids, reducing contingency padding

- Maintains year-end deadline compliance

Why ROI is even higher in winter:

Strike repair costs increase 30-50% in frozen conditions. Emergency response becomes slower and more expensive in cold weather. Delay costs amplify dramatically under compressed year-end schedules. Snow and weather destroy markings more frequently, requiring repeated locating work when not completed before severe winter conditions.

Best Practices And Technology For Winter Utility Locating

Effective winter utility locating requires multiple technologies working together. No single method detects all utility types or overcomes every winter challenge, making a combined approach essential for comprehensive protection.

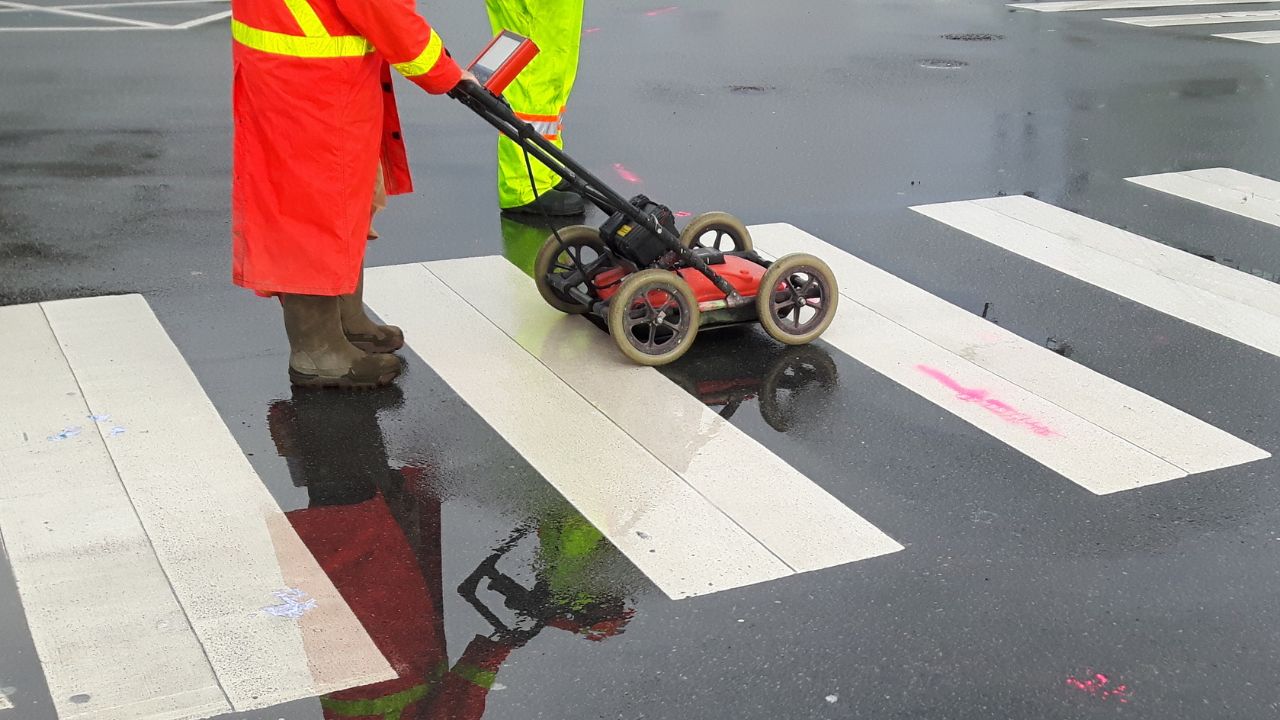

Combined technology approach:

Ground Penetrating Radar (GPR) detects both metallic and non-metallic utilities while providing depth data. Professional-grade systems range from $14,000 to $100,000. Electromagnetic (EM) locating traces metallic utilities, including gas, water, and electric lines, at a lower equipment cost than GPR. Magnetic locators detect ferrous materials through snow as effectively as through dirt. Using all three technologies together provides comprehensive coverage that single-method approaches cannot achieve.

Dual-system strategy:

The 811 public locating system provides free, legally required marking of public utilities but offers no depth data and excludes private utilities like building service laterals. Private underground utility locating services charge fees but cover both public and private utilities while providing critical depth information. Best practice combines both systems for maximum protection, 811 for legal compliance and baseline public utility identification, private locating for complete coverage, including the private utilities where most strikes occur.

Essential Winter Locating Best Practices:

- Schedule in November/early December before the ground freezes solid

- Remove snow from sites before locating for accuracy

- Use black paint and flags on snow for visibility

- Plan alternative grounding for EM equipment (may need 50-100 ft wire runs)

- Begin work immediately after receiving clearance; weather can destroy marks quickly

- Request re-markings if the weather obscures markings; stop work if the marks are not visible

- Integrate utility data directly into construction drawings and BIM models through utility mapping services

- Use vacuum excavation in critical conflict areas for visual confirmation

Technology Comparison for Winter Projects

| Method | Cost | Best For | Winter Advantage | Limitation |

| GPR | $14K-$100K equipment | Non-metallic utilities; depth mapping | Works through snow/ice | Reduced accuracy in freeze-thaw |

| EM Locating | Lower than GPR | Metallic utilities | Highly accurate once grounded | Ground rod insertion is difficult |

| Combined Approach | 1-2% project cost | Complex projects ≥$3M | Comprehensive coverage | Higher upfront cost |

Project types that benefit most:

Projects costing $3 million or more show the highest returns. Urban areas with average daily traffic exceeding 6,000 vehicles face greater impact from delays. Deep excavation projects, including bridges, new construction, and roadway widening, encounter utilities most frequently. Projects with estimated utility relocation costs at or above 3% of the budget require the precision that only comprehensive locating provides.

Safety, Compliance, And Long-Term Value

Proper utility locating protects lives and reduces liability far beyond immediate project cost savings. Winter conditions that slow emergency response make prevention the only practical safety strategy.

Safety improvements:

Professional locating prevents worker exposure to gas leaks, electrical shocks, and hazardous materials released during utility strikes. This protection eliminates excavation accidents that cause 1,906 injuries nationwide annually. Reducing utility strikes decreases liability from neighboring property damage and service interruptions. Slower emergency response times in winter weather make prevention critical; once a strike occurs in winter conditions, help arrives late while dangers escalate.

Compliance benefits:

Comprehensive utility locating meets legal 811 requirements while satisfying OSHA excavation safety standards. This compliance prevents regulatory fines and stop-work orders that compound project delays. Proper documentation supports permitting requirements and provides legal protection if conflicts arise despite best efforts.

Long-term cost savings:

Preventing strikes reduces future maintenance costs on protected utilities. Insurance companies recognize demonstrated risk management practices with lower premiums. Each project builds a utility database that reduces costs on future work in the area.

Avoiding strikes protects a contractor’s reputation and maintains bidding competitiveness; one major winter strike can eliminate a contractor from consideration on future projects. Prevention stops cascading damage where one strike compromises multiple adjacent utilities.

Long-Term Savings by Utility Type

| Utility Type | Strike Repair Cost | 5-Year Maintenance Savings (Avoided Damage) |

| Water Main | $10,000-$50,000 | $15,000-$75,000+ |

| Gas Line | $25,000-$100,000+ | $50,000-$175,000+ |

| Electrical Cable | $15,000-$75,000 | $35,000-$125,000+ |

| Fiber Optic | $50,000-$250,000 | $100,000-$375,000+ |

Implementing Utility Locating As Standard Practice

Converting utility locating from an optional precaution to a standard practice requires systematic integration into project planning. The proven returns justify making comprehensive locating automatic rather than discretionary.

Immediate action steps:

Assess project profile first; projects at or above $3 million in complex urban environments show the highest returns. Budget 1-2% of project cost for comprehensive SUE services during initial planning, not as an afterthought. Schedule early by completing all locating work in November or early December before severe weather arrives. Use the dual approach of 811 public locating plus private locating services. Employ multiple technologies: GPR plus EM plus records research plus vacuum excavation for critical conflict areas.

Plan for winter adaptations, including snow removal, black marking materials, and alternative grounding solutions. Integrate utility location data directly into construction drawings and BIM models. Monitor and verify marks before excavation begins; request immediate re-markings if weather events obscure markings.

Winter Construction Success Through Proactive Utility Locating

Winter construction projects face elevated risks and costs from utility strikes, but comprehensive utility locating delivers proven returns that far exceed the investment. Research across multiple studies consistently demonstrates $2.73 to $22.21 saved for every dollar spent on SUE services, returns achieved by preventing strikes that cost 30-50% more to repair in frozen conditions. Projects at or above $3 million in complex urban environments show the highest returns, particularly when locating work occurs in November or early December, before the ground freezes solid.

The combination of GPR, electromagnetic locating, and vacuum excavation provides comprehensive protection that single-method approaches cannot match. Beyond immediate cost savings, proper utility locating prevents the 1,906 injuries that occur annually from utility strikes, protects contractor reputation, maintains year-end deadline compliance, and builds valuable utility databases for future projects.

Protect your winter construction project from costly utility strikes and deadline-threatening delays. Contact our utility locating experts today to schedule comprehensive SUE services before the ground freezes.