Trench excavation is a fundamental aspect of building construction, serving as the backbone for laying foundations, pipes, cables, and other crucial underground utilities. This meticulous process ensures the stability and functionality of the structures we build

However, it’s essential to recognize that trench excavation is far from a simple dig in the ground; it’s a complex operation that demands careful planning, execution, and adherence to safety measures from trusted utility locating services.

In this comprehensive guide, we will delve deep into the world of trench excavation in building construction, exploring its significance, safety procedures, common uses, and more. So, let’s dig in, figuratively speaking.

The Significance of Trench Excavation

Before we delve into the intricacies of trench excavation, let’s understand why it’s such a vital step in building construction.

- Foundations – One of the primary uses of trench excavation is to lay the foundations of buildings. A solid foundation is essential to ensure that structures remain stable and secure over time. The trench provides the necessary space for concrete footings, ensuring they are at the correct depth and alignment.

- Piping and Cabling – Trenches are also instrumental in the installation of various utility lines, such as water, sewer, gas, electricity, and communication cables. These lines must be placed underground to protect them from external factors and accidental damage.

- Drainage and Irrigation – Trenches are employed to create drainage systems that divert excess water away from construction sites, mitigating the risk of flooding and erosion. In addition, irrigation systems are installed in trenches to provide water for lawns, gardens, and landscaping.

Safety First: The Key to Successful Trench Excavation

Trench excavation can be a hazardous undertaking, given the potential for collapses, utility strikes, and other risks. That’s why adhering to safety measures, including the use of a utility locator, is paramount. Here are some crucial steps to promote safety during trench excavation:

- Planning – Before any excavation work begins, meticulous planning is essential. This includes identifying the location, depth, and width of the trench, as well as the presence of all underground utilities.

- Shoring – Trenches of a certain depth must be shored up to prevent collapses. Various shoring methods, such as trench boxes, shoring plates, and braces, can be used to ensure worker safety.

- Dewatering – In cases where groundwater levels are high, dewatering may be necessary to lower the water table and create a safe working environment. This process involves the use of pumps or sumps.

- Safety Equipment – All workers involved in trench excavation must wear the appropriate safety gear, including hard hats, safety glasses, steel-toed boots, and any other equipment necessary to protect against specific hazards.

Common Uses of Trench Excavation in Construction

Trench excavation plays a pivotal role in several aspects of construction:

- Foundations – Trenches are meticulously excavated to create the foundation for a building, ensuring stability and preventing settling or collapse.

- Piping – Trenches are essential for the installation of pipes that carry water, sewage, gas, and other utilities. These pipes are buried deep enough to safeguard them from frost damage and other potential hazards.

- Cables – Trenches are used for laying cables that provide electricity, telephone, and other communication services. These cables are buried at a depth that shields them from accidental damage.

- Drainage – Trenches are dug to establish drainage systems that remove excess water from construction sites, preventing flooding and erosion.

- Irrigation – Trenches are employed for irrigation system installation, ensuring lawns, gardens, and landscaping receive the necessary water supply. The depth of irrigation pipes protects them from damage caused by lawnmowers and other equipment.

Types of Trenches

Trenches can vary in terms of purpose and design. Here are some common types:

- Open Trenches – These are the standard trenches used for various construction purposes, such as laying utilities and foundations.

- Permanent Trenches – As the name suggests, these trenches are intended for long-term use and are typically employed for utilities like water and sewage lines.

- Temporary Trenches – Temporary trenches are often used for shorter durations and may be created for specific construction phases.

- Communication Trenches – These trenches are specifically designed for laying communication cables, such as those used for telephone and internet services.

Trench Excavation Safety and Regulations

Safety should never be compromised during trench excavation. The Occupational Safety and Health Administration (OSHA) has set stringent regulations and guidelines to ensure worker safety during trenching and excavation activities.

These regulations include the requirement for protective systems (such as shoring, sloping, or trench boxes) for trenches deeper than a specified depth. Employers are also obligated to conduct regular inspections, provide appropriate safety training, and address hazardous conditions promptly.

Types of Soils and Ground Conditions

Understanding the types of soils and ground conditions is critical when planning trench excavation. Different soils have varying levels of stability and cohesion.

Sandy or gravelly soils are generally more stable and require less shoring, while clay or loamy soils can be more prone to collapse. A geotechnical analysis of the soil composition is often necessary to determine the appropriate excavation and shoring methods.

Common Challenges and Risks in Trench Excavation

Despite the importance of trench excavation, it comes with its share of challenges and inherent risks:

- Cave-ins and Collapses – Trenches, especially those of considerable depth, are susceptible to cave-ins and collapses. This risk is particularly high when excavating in loose or unstable soil. Proper shoring and protective measures are essential to mitigate these dangers.

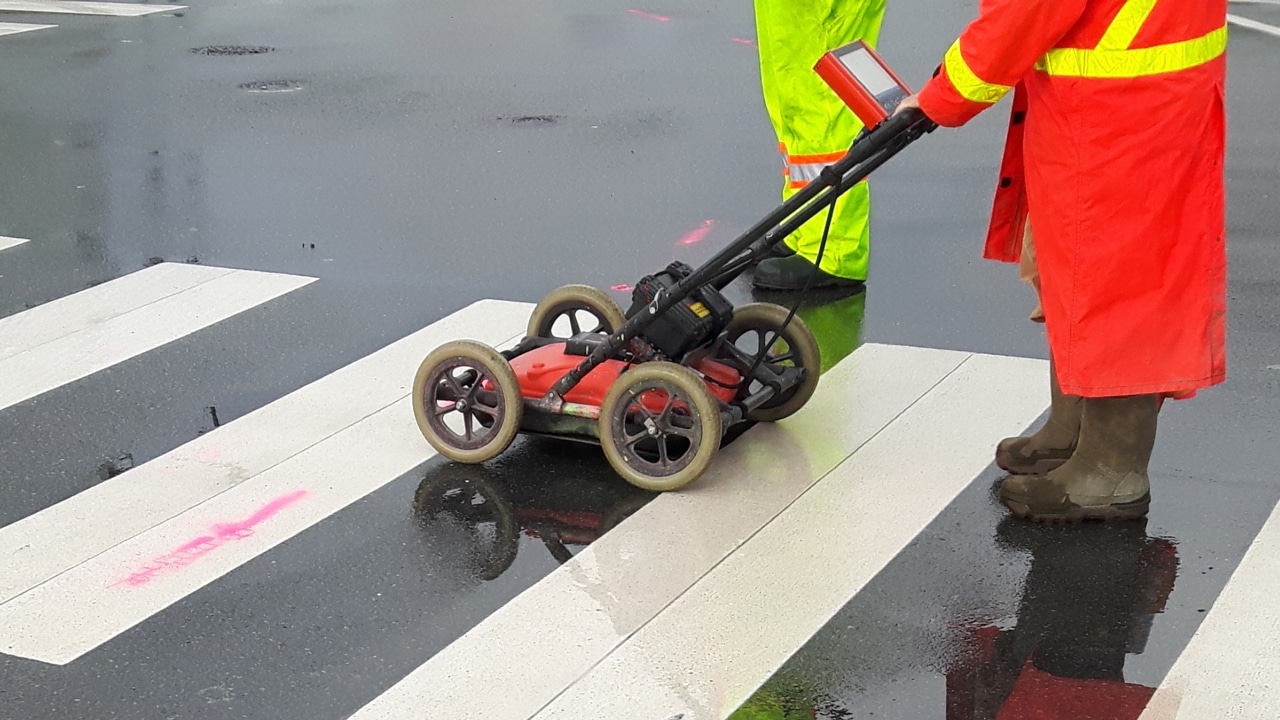

- Utility Strikes – One of the most significant risks associated with trench excavation is inadvertently damaging underground utility lines. Striking electrical, gas, or water lines can lead to catastrophic accidents, service disruptions, and costly repairs. Thorough private utility locating and verification before excavation are critical to avoid such incidents.

- Soil Stability Matters – The type of soil in which the trench is excavated plays a crucial role in safety. Soils with poor stability can lead to wall failures and collapse. It’s essential to assess soil conditions and take appropriate precautions.

Trench Excavation: A Safer Alternative

As technology advances, safer and more efficient methods for trench excavation are continually emerging.

Vacuum excavation, for instance, is gaining popularity as a non-destructive method for potholing utilities. This method utilizes powerful vacuum systems to remove soil, exposing underground utilities without the need for heavy equipment and potential utility damage.

Call Us Before You Dig – Trust Util-Locate for a Safe Trench Excavation!

At Util-Locate, we understand the critical role trench excavation plays in construction projects. Our expert team specializes in underground utility locating services, ensuring that your trench excavation proceeds smoothly and safely. With our cutting-edge technology and unwavering commitment to safety, we help you avoid costly accidents, utility strikes, and project delays.

Don’t take unnecessary risks. Partner with Util-Locate for comprehensive utility locating services, adherence to safety protocols, and efficient trench excavation. Contact us today at 888-885-6228 to discuss your project’s needs and benefit from our industry-leading expertise. Your safety and the success of your excavation project are our top priorities.