Key Takeaways

- 3D scanning ensures accurate detection of underground utilities.

- Enhances safety by providing exact locations of underground infrastructure.

- Saves time and money by ensuring projects stay on schedule.

- Collects comprehensive data on a wide range of underground utility lines.

- Versatile technology is suitable for various types of subsurface utility investigations.

3D scanning for utility mapping offers numerous benefits, such as accurately identifying the precise location of underground utilities and enhancing the efficiency of construction projects. This advanced technology provides detailed and accurate views of underground utility locations, helping project managers and utility locators make informed decisions that keep projects on track and within budget.

The use of 3D scanning in utility mapping provides significant advantages by delivering a detailed and accurate view of underground utility locations. This technology aids in identifying subsurface utilities, mitigating safety risks, and ensuring that a construction project is completed on time and within budget.

Advantages of Using 3D Scanning to Locate Underground Utilities

3D scanning technology offers significant advantages for utility mapping, including enhanced accuracy, efficiency, cost savings, safety, and comprehensive documentation. Its versatility and ability to improve planning, design, and collaboration make it an indispensable tool in modern utility management.

Accurate Detection and Location

One of the primary benefits of 3D scanning is its ability to accurately detect and locate underground utilities. Traditional methods often rely on outdated maps and guesswork, which can lead to errors and accidents. In contrast, 3D scanning uses advanced ground penetrating radar (GPR) and remote sensing technologies to create precise maps of the subsurface utility environment.

Ground-penetrating radar emits energy waves that penetrate the ground and reflect off different materials, such as pipes and cables. These reflections are captured and processed to generate detailed images, showing the exact locations of underground pipes, cables, and other underground infrastructure. This accuracy is crucial for avoiding damage during excavation and ensuring that underground utility infrastructure remains intact.

Enhanced Safety

Safety is a paramount concern in any construction project, and 3D scanning significantly enhances safety by providing clear and accurate information about underground utilities. By knowing the exact locations of underground utility lines, workers can avoid accidental strikes, which can be dangerous and costly.

Accidental strikes on underground utility infrastructure can lead to severe consequences, including injuries, service disruptions, and financial losses. By using 3D scanning, project managers can minimize these risks and ensure a safer working environment for their teams. This proactive approach not only protects workers but also prevents costly delays and repairs.

Efficiency and Time-Saving

Time is money in the construction industry, and 3D scanning helps save both by providing real-time data that enables project managers to make informed decisions quickly. The detailed and accurate information obtained from 3D scans eliminates the guesswork and reduces the likelihood of encountering unexpected underground utility issues during excavation.

With 3D scanning, projects can proceed more smoothly and efficiently. The ability to identify underground utility locations accurately means that excavation and construction can be planned more effectively, reducing the time spent on site and minimizing disruptions. This efficiency is crucial for keeping projects on schedule and ensuring that they are completed on time.

Comprehensive Data Collection

3D scanning gathers extensive data on a wide range of underground utility locations. It utilizes remote sensing technologies to capture images and detect underground utility lines, providing a detailed map of the subsurface utility environment. This comprehensive data collection is invaluable for subsurface utility investigations and helps in creating accurate records of underground utilities.

The data collected by 3D scanners includes information on the type, size, and depth of underground utilities. This information is essential for planning and executing construction projects safely and efficiently. It also allows for better coordination between different stakeholders, such as utility companies, contractors, and project managers, ensuring that everyone has access to the same accurate information.

Versatility

3D scanning is a versatile technology that can be applied in various scenarios, including subsurface utility investigations and private utilities. It can accurately map a wide range of types of utilities, from water and gas lines to electrical conduits, aiding in comprehensive underground utility mapping. This versatility makes it an invaluable tool for different types of construction projects, whether they involve residential, commercial, or industrial sites.

The ability to map different types of underground utilities accurately is particularly important for projects that require excavation or drilling. By knowing the precise location of these utilities, project managers can avoid damaging them and ensure that the construction work proceeds smoothly. This versatility also makes 3D scanning an essential tool for utility companies and municipalities, which need to maintain accurate records of their underground utility networks.

By embracing 3D scanning for utility locating services, you can significantly improve the precision and safety of your construction projects, ensuring they are completed on time and within budget. This technology not only enhances efficiency but also provides peace of mind, knowing that your project is built on a solid foundation of accurate and comprehensive utility mapping.

Ground Penetrating Radar: How It Works

3D scanning employs ground-penetrating radar and other remote sensing technologies to emit energy waves that penetrate the ground. The reflections from these waves are then captured and processed to create detailed images of the underground utility infrastructure. This method is non-invasive and highly effective in locating underground utility lines without digging.

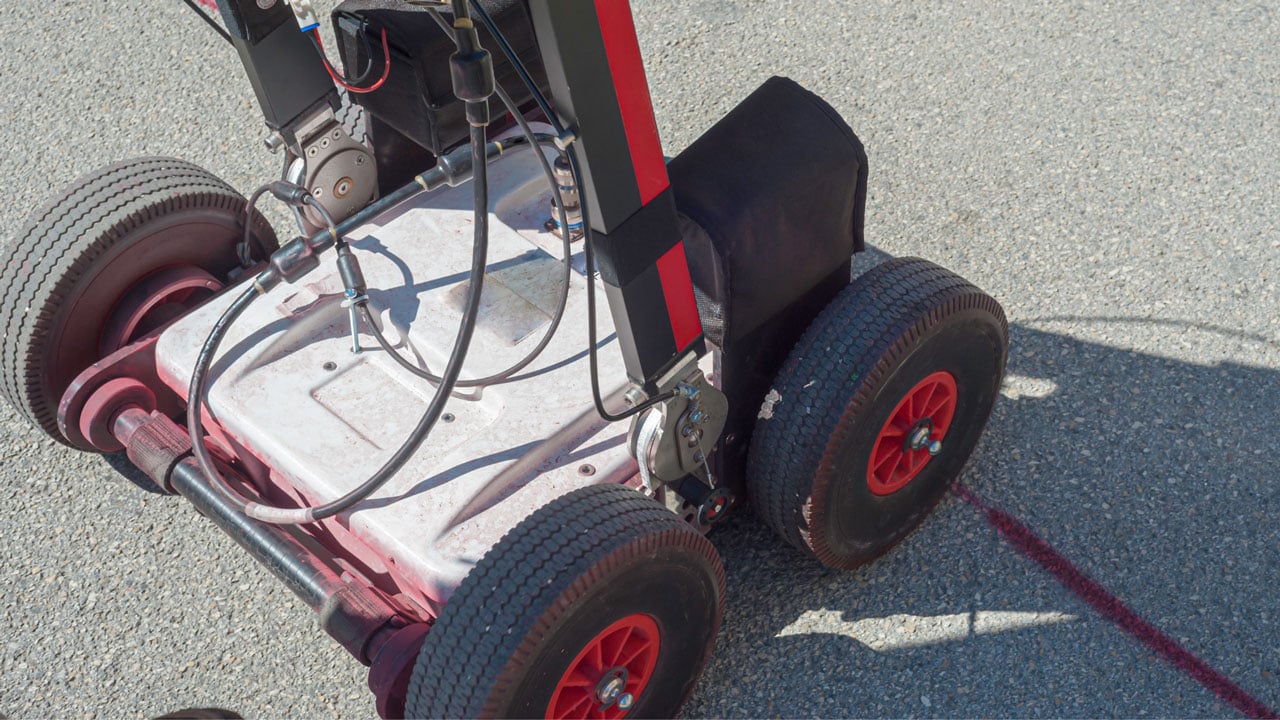

The process begins with the deployment of a 3D scanner over the area of interest. The scanner emits energy waves that travel through the ground and reflect off different materials, such as metal, plastic, and concrete. These reflections are captured by the scanner and processed to create a detailed 3D map of the underground utility environment.

The resulting images provide a clear and accurate representation of the underground utility network, showing the exact locations of underground pipes, cables, and other infrastructure. This information is then used by utility locators and project managers to plan and execute construction work safely and efficiently.

Find Expert Utility Locating Services Today!

Experience the benefits of cutting-edge 3D scanning technology with Util-Locate’s utility locating services. Our expert utility locators are equipped with the latest tools to provide precise underground utility detection and mapping.

Don’t wait until it’s too late – ensure your construction project runs smoothly and safely. Contact Util-Locate now and let us help you locate underground utilities with unmatched accuracy and efficiency.