Key Takeaways

- Thorough planning is essential to avoid common mistakes like inadequate size and poor location, which can affect the health and maintenance of a pond.

- Avoid areas under trees and low-lying areas prone to flooding. A well-chosen location balances sunlight and accessibility, benefiting the pond’s health and aesthetics.

- Ensuring correct installation techniques, including using suitable pond kits and following manufacturer guidelines, is vital for the longevity and functionality of a pond.

- Regular testing and water quality maintenance are crucial. Using filtration systems and beneficial bacteria helps maintain a clean and balanced aquatic ecosystem.

- Avoid overcrowding with plants and fish. Proper stocking densities and adequate planting ensure a healthy, manageable pond ecosystem.

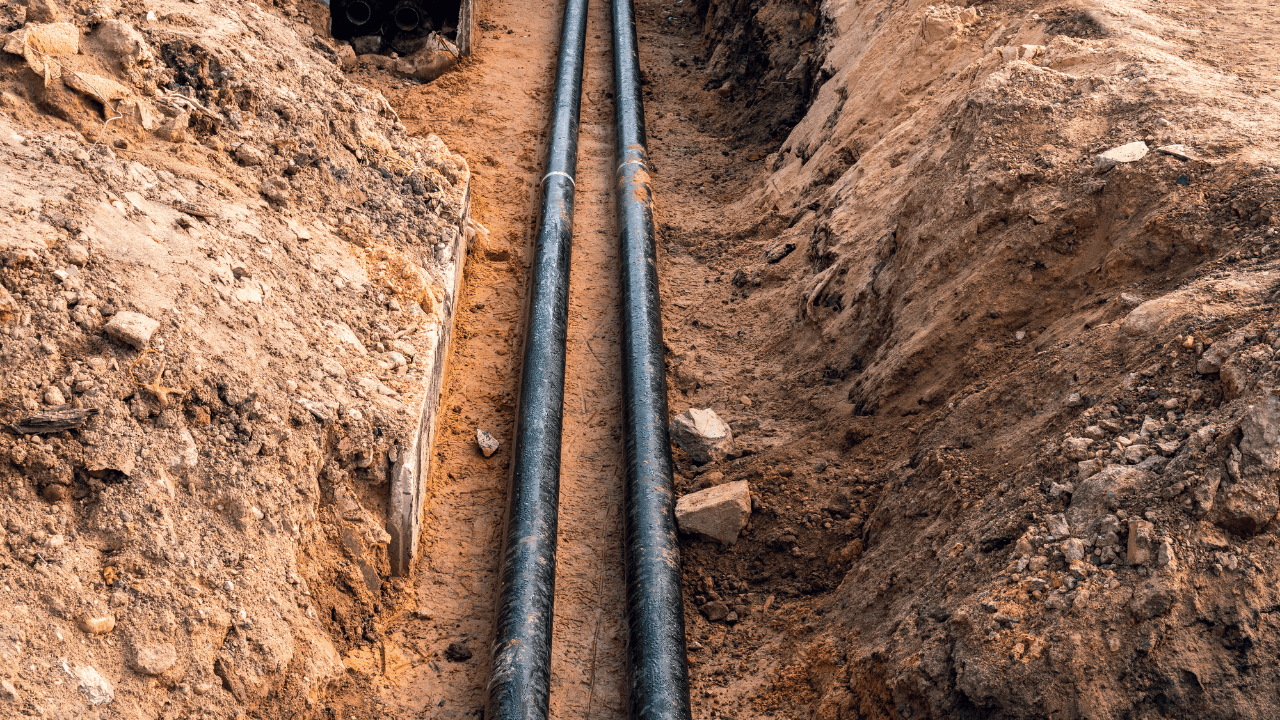

Locating underground power lines is a critical task in construction and excavation projects. Striking buried utilities can lead to costly delays and, more importantly, create dangerous working conditions.

Yet, even with modern tools and resources, errors often occur due to oversight or insufficient planning. To ensure a successful project, it’s vital to understand these common pitfalls and take steps to avoid them.

From using the right utility locating services to understanding and using underground utility locator methods correctly, every step matters. Below, we break down the common errors and offer practical ways to avoid them for a seamless, efficient project.

Common Errors to Avoid in Electrical Power Line Locating

Locating underground power lines requires precision and expertise to prevent costly and dangerous errors. Here are some errors you need to know and avoid.

1. Overlooking Pre-Project Planning

One of the most frequent errors in underground power line locating is rushing into the field without a precise and thorough plan. Without a clear understanding of where utility conduits are situated, projects run the risk of interference with power lines.

In worst-case scenarios, failure to properly plan can cause serious injuries and project delays.

Before any digging begins, a well-planned excavation project should involve these essential steps:

- Consult with utility locating services to gather expert insight and assistance in marking underground utilities.

- Examine all available site data to verify where power lines and other conduits may be located.

- Outline every step of the excavation carefully, ensuring that each phase considers utility locations and potential hazards.

- Gather as much information as possible about the utility layout.

- Account for the fact that not all locations follow a standardized layout.

- Avoid a one-size-fits-all approach, as this can lead to serious issues.

Additionally, early coordination with local utilities is essential, as they can provide insights into potential power lines or utility conduit locating needs unique to your project site. A little extra time in the planning phase can save both time and money down the road.

2. Relying Solely on Maps or Outdated Records

Many project managers make the mistake of relying on old maps or records of utility lines, assuming they reflect all changes. However, utility networks are constantly changing.

Recent modifications, additions, or repairs to underground power lines and conduits may not be updated in these documents. Relying on outdated information can lead to critical errors, including the misidentification of lines.

To avoid this, pair traditional record-keeping with reliable underground electrical line locating tools.

One particularly effective approach is to combine map data with advanced technology, such as ground-penetrating radar (GPR) and electromagnetic sensors. These tools allow for a comprehensive and up-to-date scan of the area, highlighting both marked and previously undocumented lines.

This method provides a complete view of the underground layout, ensuring a safer and more accurate process of locating underground conduits that minimizes the chances of accidental line strikes.

3. Ignoring Marking Errors on Site

Accurate marking is essential in locating underground power lines. Even minor errors in marking can lead to significant issues during excavation, potentially resulting in power line damage and project setbacks.

Common reasons for inaccurate marking include miscommunication, human error, or the use of unsuitable tools. Professional underground utility locating services offer precise marking services, which can be critical for success.

Another frequent issue is failing to double-check marking placements before excavation begins. Verifying marks multiple times and keeping open communication with the utility locator helps prevent errors and costly repairs.

Teams should also use temporary paint or stakes in high-traffic areas to help everyone on site stay aware of power line locations. Taking these steps creates a safer work environment and helps keep the project timeline on track.

4. Failing to Use the Right Locating Equipment

Using improper or outdated locating equipment is another common pitfall. Many projects fail to leverage advanced underground utility locators, resulting in incorrect or incomplete readings.

Each line type—whether it’s electrical, water, or gas—requires specific locating tools for optimal accuracy. The risks of misidentifying lines or conduits increase significantly when the incorrect equipment is used. Knowing the appropriate equipment for each task is a crucial aspect of power line locating.

Investing in the latest technology, including GPR and electromagnetic sensors, can make a substantial difference. High-tech equipment provided by professional utility locating services offers greater accuracy and reliability, which helps avoid unexpected line strikes and costly repairs.

Advanced tools also allow operators to detect deeply buried lines or conduits that might otherwise go unnoticed with conventional tools. These high-precision instruments are especially useful in areas with dense networks of underground utilities.

5. Not Understanding Local Utility Marking Standards

Inaccuracies often occur when project teams are unaware of local utility marking standards. Color-coded markings are commonly used to identify different types of utilities, but standards can vary between regions.

Not recognizing these standards can lead to confusion and the misidentification of power lines or other utility conduits. Failing to adhere to these standards increases the risk of accidents and adds unnecessary complications to the project.

Before beginning any utility locating work, ensure your team understands and follows the local utility color-coding standards. Each color represents a different type of lifestyle, red for electrical, blue for water, yellow for gas, and so forth.

Confirming these guidelines with a professional underground utility locating team will provide clarity and prevent dangerous mistakes. A small investment in understanding these local codes can make a big difference in project safety.

6. Misinterpreting Data from Locating Devices

A common issue in utility locating is misinterpreting data obtained from locating devices. Ground-penetrating radar (GPR) and electromagnetic sensors generate complex data that require expertise to interpret correctly.

Misreading this data can result in excavation over incorrect spots, putting power lines and utility conduits at risk. Incorrect data interpretation is particularly risky for new or less experienced operators who may not yet fully understand how to handle certain readings.

Training operators on how to interpret GPR and other data is essential. Professional utility locating services employ trained technicians who are skilled in reading these devices, ensuring the accuracy of the information gathered.

Additionally, thorough calibration of equipment before starting any project helps to avoid misreads and provides precise data. By employing trained professionals and consistently calibrating equipment, you increase the likelihood of accurate and efficient power line locating.

7. Overlooking Soil Conditions and Environmental Factors

Environmental factors can impact the accuracy of underground utility locating. Conditions such as wet soil, rocky terrain, or temperature variations can affect the performance of locating equipment.

For instance, electromagnetic signals are often weaker in waterlogged areas, which can lead to inaccurate readings. Similarly, rocky terrain can interfere with GPR signals, obscuring the presence of utility conduits.

To counter these environmental challenges, plan for variable conditions and use equipment suited to the specific soil type. Teams should also account for environmental limitations during initial planning phases and consult with experienced utility locating services.

Addressing these factors early on ensures a more accurate locating process, even in challenging environments, and prevents unexpected delays or issues during excavation.

Take Charge of Utility Locating with Professional Assistance

For a successful and safe project, avoid common mistakes in utility locating by reaching out to Util-Locate.

Partner with us to access advanced tools, precise marking, and expert knowledge of environmental and local standards.

This collaboration empowers your team to work confidently and efficiently. Take control of your power line locating needs with our expert support and state-of-the-art equipment, ensuring a streamlined and safe project every time.